Betolar: Towards concrete sustainability

Futurice supported Betolar in identifying the right digital strategy for their next-generation building material solution and making the development process more data-driven, scalable, and efficient.

Technologies used

- Vue.js

- TypeScript

- PostgreSQL

- Azure

- Python

The challenge

The construction industry is among the most polluting sectors, responsible for approximately 20% of global CO2 emissions. Also, emissions from building materials account for more than 40% of the total life cycle of a building, mainly from the cement used in concrete, which accounts for 7% of global CO2 emissions.

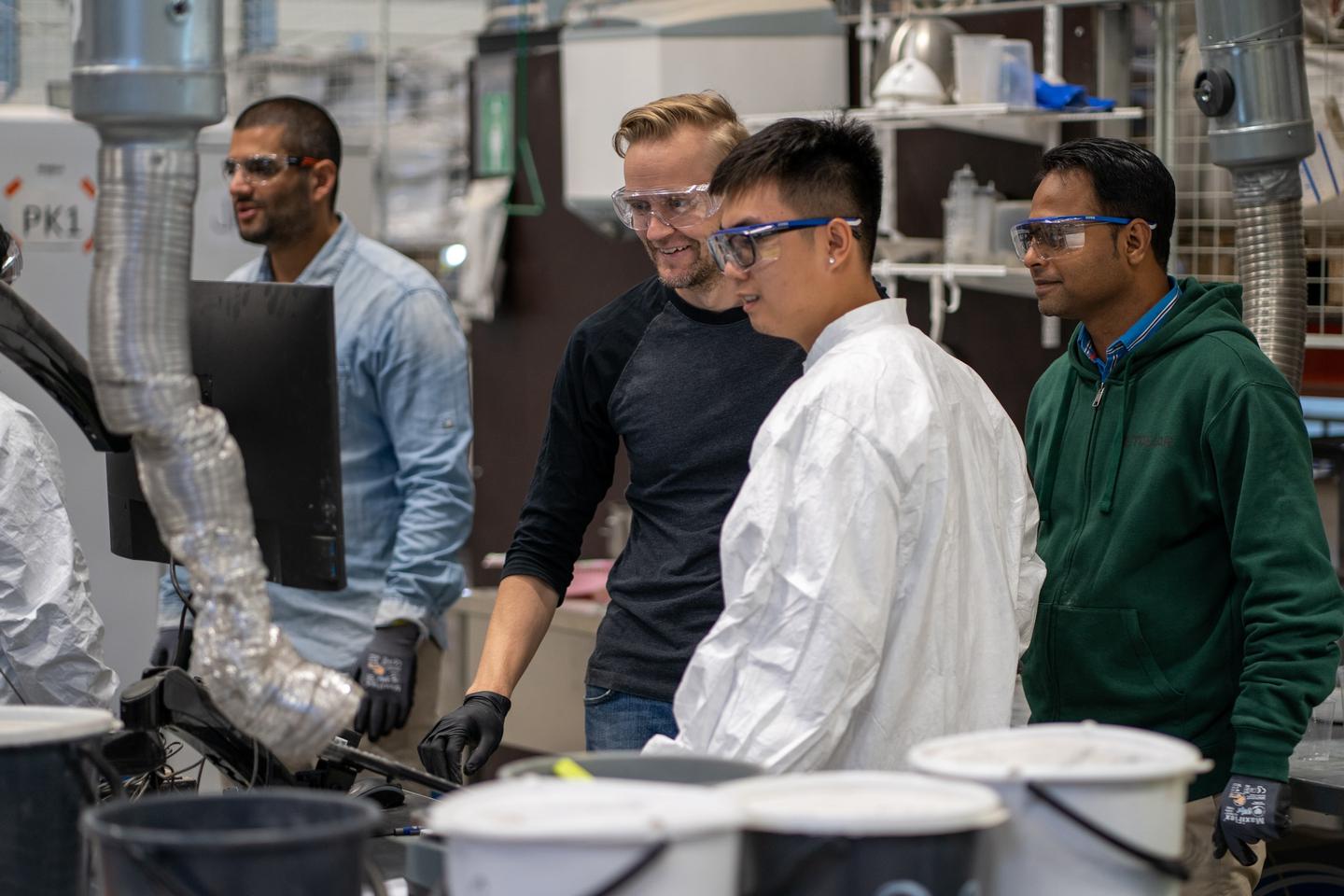

Betolar’s next-generation building material, Geoprime®, enables concrete production without pollutive cement by transforming industrial side streams into a sustainable business. Betolar had succeeded in replacing cement with a side stream-based material that matches traditional concrete in attributes such as strength but reduces the carbon footprint by up to 80%.

The challenge was to make R&D process more effective. The key was finding efficient ways to use the different side streams, even though material availability and features might vary depending on location.

Impact and outcomes

Helped make the R&D process more efficient: leveraging data and digital tools

Improved quality, efficiency, and customer satisfaction: competitiveness and adaptability on a global scale.

Faster and more rewarding ways of working: tools that people want to use.

What we did

Betolar had identified scalability in the Lab and RnD operations as an enabler for its strategic objectives. We started the collaboration by jointly distilling the next stepping stones and identified the further development of Betolar’s Laboratory Information Management System (LIMS) and the faster analysis of the experimental results as high-priority items.

Betolar’s existing LIMS tool did not fulfill the increased requirements and had acquired some tech debt. Our objective was to help Betolar manage its lab more efficiently and adapt quickly to changing needs. We achieved this by improving the Developer Experience, enhancing the product quality, introducing new software engineering practices and refining its architecture.

In addition to enhancing the existing LIMS, we contributed to the planning of Betolar’s architecture modularization. These efforts paved the way for future improvements and transformations for both the LIMS and their whole cloud-based digital platform, which is a key part of Betolar’s long-term strategy.

In parallel, we developed an R&D analytics tool for the researchers to collect and integrate data from various sources, such as lab experiments and pilot trials. The information may include structured and unstructured data for, e.g., analyzing and creating charts, graphs, and reports.

Our agile ways of working and product-building culture, in which running quick iterations and gathering quantitative and qualitative feedback is a central part of development, made an important contribution, too. For example, we worked closely with the researchers and the rest of the Betolar team, bringing them around the same table, and proposing use cases that were validated and measured as early as possible.

We have worked with Futurice to push our digitalization further. The cooperation with Futurice has been very smooth and their professionals have provided the needed competence to accelerate our development. Scalable laboratory and R&D would not be possible without professional and innovative digital solutions. Futurice has been an important part of Betolar’s digitalization journey towards creating greener construction materials.

Why it matters

Thanks to data capability, usability, automation, and streamlined workflows, the Geoprime® product development process is now more efficient and scalable.

The R&D tool helps Betolar’s researchers and engineers speed up data analysis considerably. In addition, it increases the amount of data involved in iterating Geoprime® recipes. The tool has helped the R&D team improve their efficiency individually and as a team by providing tools to document and share the findings. Due to the value provided and the emphasis on user experience, the tool is now used by the vast majority of the R&D team daily and has become a central part of the workflow.

The agile ways of working – creating a prototype in a diverse team, getting feedback, and then iterating in rapid sprints – help avoid building services on false or outdated assumptions. When the new use case is released, it keeps pace with changing user needs and business requirements. Agile software development delivers high-quality and people-oriented use cases quickly and cost-effectively.

About Betolar

Betolar Plc is a Finnish materials technology company that offers the production of sustainable and low-carbon concrete with the Geoprime® solution. The solution converts industrial side streams into a cement substitute. Betolar's artificial intelligence innovation can significantly reduce CO2 emissions compared to traditional cement-based concrete production by optimizing existing manufacturing processes, supporting solution development with advanced analytics and creating global markets for side streams. Betolar's mission is to help reduce CO2 emissions and the use of virgin raw materials.

Talk to us

Get in touch

Looking for help with an idea, brand new brief or in-flight project? Drop us a line for a straightforward conversation.